Inventory costing is the process of assigning a monetary value to the inventory in the hand of a business entity at any point in time. One of the main methods used for inventory costing is First in First out or FIFO.

FIFO stands for “First-In, First-Out”. The cost flow assumption uses FIFO to base the calculation of the Cost of goods sold. It uses the oldest products in a company’s inventory first, which means the costs paid for the oldest products is the one used in the calculation.

[widget id=”custom_html-24″]

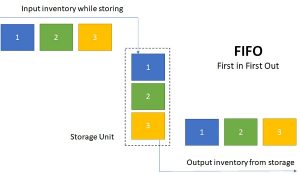

In FIFO, the first goods you sell are the ones that you purchased or manufactured first. The image below shows the movement of inventory in FIFO.

The advantages of using FIFO as an inventory valuation method are:

- It is easy to understand and universally accepted.

- It follows the natural flow of inventory which is that the oldest product is sold first, with accounting going by those costs first. This makes bookkeeping easier with less chance of mistakes.

- Less waste (a company truly following the FIFO method will always be moving out the oldest inventory first).

- The remaining products in inventory will be a better reflection of market value.

- Higher profit.

This method gives a very accurate picture of a company’s finances, which allows proper planning of future finances.

[widget id=”custom_html-40″]

In Versa

Due to the ease of business application, Versa Cloud ERP has its inventory accounting and calculations based on FIFO.

During the course of business, an enterprise continuously purchases stock for manufacturing. The system values all stocks differently, as it takes into account the market fluctuations. Versa bucketizes the received goods as per their prices and purchase durations.

FIFO forms, the basis of product pricing, extending its effects to other functions such as landed cost. Landed cost is the final cost of products including all associated shipping and logistics costs required to get the goods delivered to a final location.

Because FIFO bucketizes the goods received, it enables Lot and Serial number tracking. Lot or serial number tracking traces the products end-to-end, from the manufacturer through the supplier to the customer or vice-versa.

[widget id=”custom_html-26″]

In addition, this process keeps track of which customers received specific lots, which allows managers to account for product movement via various auto-generated reports.

In application, if a business uses FIFO, tracing a particular price to the original lot used in production can be done with ease.

Above all, it has wide applicability in manufacturing and pharma. It enables tracing of the final product to a particular factory and establishes a chain of ownership.

With all the concepts combined and based on FIFO, it allows accurate reporting and calculation of the Cost of Goods Sold on a month-to-month basis, therefore reflecting the true value in the PNL statements.

To summarize, FIFO acts as a carrier for concepts like COGS, landed cost, lot tracking, and serial number tracking; making it (FIFO) fit for achieving fine-grain details in any business process.

Know More about our VERSA-tility Sign-Up!

[widget id=”custom_html-29″]