Optimize your warehouse operations for efficiency and productivity with expert strategies and innovative solutions

Warehouses are busy places that store and move products to customers. Two important jobs in warehouses are packing and picking. This article explains what packing and picking mean and how to do them very well.

What is Warehouse Packing?

Packing means getting orders ready to ship out to buyers. Warehouse workers take requested items and pack them in shipping boxes. Then they send the boxes off to the customer.

Packing includes many steps:

- Sorting different products into orders

- Placing items neatly into boxes or bags

- Wrapping fragile goods safely

- Taping boxes closed

- Weighing packages and adding mailing labels

- Stack boxes neatly onto pallets for loading

What is Order Picking?

Picking means finding the products buyers asked for. Warehouse pickers locate items that are stored on shelves, racks, bins or other areas. They follow instructions to collect the exact amounts of each thing ordered.

Pickers bring those products to the packing area. From there, packers can count the items and pack orders for delivery. Popular picking methods include:

- Discrete picking – Getting all items for one full order then moving to the next order

- Batch picking – Picking all needed amounts of one product at once

- Zone picking – Dividing the warehouse into different areas and only picking from assigned zones

- Wave picking – Releasing big groups of orders at set times and picking them in batches

Warehouse Operations: Factors that Impact Packing and Picking

Many things affect how fast and precise warehouses can pack and pick up orders. Here are key factors managers should address:

Warehouse Layout

- Place high-demand products in easy-to-access areas

- Create wide aisles for smooth material flow

- Use clear floor markings and signs

Storage Equipment

- Pallet racks, shelves, and bins should arrange items logically

- Mobile racks and carousels save floor space

Peak Order Volumes

- Holiday orders can overwhelm, plan ahead

- Have extra workers and space ready

Inventory Organization

- Assign SKU numbers and keep detailed counts

- Make sure popular products are well-stocked

Staffing and Technology

- Training for safe, efficient habits

- Smart warehouse tech like barcode scanners can help

Data Tracking

- Record metrics like lines picked per hour

- Find ways to improve by studying data

Warehouse Operations: Tips for Improving Efficiency

How can managers enhance packing and picking? Here are great tips:

- Design layout to avoid jam-ups – Use aisle width, storage size, and floor marks to guide smooth traffic flows.

- Combine discrete orders – Picking all quantities of one SKU at once saves time.

- Go paperless with scanners– Scan each item instead of ticking on paper. Apps can guide the next pick spot.

- Train staff to multitask – Employees able to pack, pick, sort, and prep shipments add flexibility.

- Plan for seasonal peaks creatively – Involve other departments to help handle holiday order floods.

- Add robots where useful – Let machines handle walking, lifting, and transport to ease labor shortages.

As customer demands grow, packing and shipping get more complex. Spotting areas to simplify processes helps warehouses adjust. Companies that take time to choose systems and layouts supporting smooth fulfillment will gain an edge. Employees also need engagement to see and meet improvement goals. With clear metrics guiding better training and procedures, teams can achieve order accuracy and speed.

Improving Warehouse Layouts for More Efficient Picking Routes

Analyzing warehouse traffic flow and order data reveals high-volume pick zones. Managers can designate the most accessed inventory to prime locations near shipping areas and convenient aisles. Widening major aisles prevents bottlenecks, while markings distinguish main walkways. Smaller branch aisles organize the remaining items logically. Streamlined picker movement equals faster fulfillment.

Warehouse Operations: Leveraging Picking Best Practices

Discrete order picking requires covering more ground, while batch picking one product minimizes redundancy. Though batch picking needs subsequent sortation, grouping orders cut travel distance up to two-thirds. Zone picking limits trips by assigning pickers specific areas, ideal for larger warehouses. For high volumes, wave picking lets managers release orders in batches for just-in-time execution. Employing these methods right-sizes approaches to order profiles.

Installing Supportive Picking Technology

Warehouse management systems centralize data for real-time inventory lookup and order assembly prompts that optimize routes. Handheld RF devices receive directions, scan items, print shipping labels, and confirm fulfillment for paperless processing. Pick-to-light racks illuminate shelving locations, with order quantities displayed on LED screens. Voice technology narrates SKUs and quantities to gather hands-free. Error-proof design prevents items from lighting up until stowed.

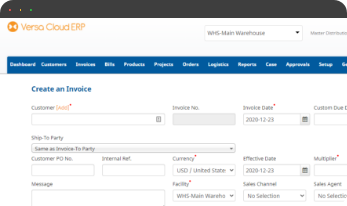

Streamlining Warehouse Operations with Versa Cloud ERP

As this article outlines, warehouses must continuously identify and implement greater efficiencies in key functions like packing and picking. Improving layouts, processes, technology, and labor helps meet customer demands for faster, flawless fulfillment.

However, optimizing the four walls of the warehouse represents only part of the equation. Inventory moves fluidly between sites – from suppliers, across production floors, through distribution centers, and onto retail shelves. Disconnects between departments reduce visibility and productivity.

This underscores the need for a modern ERP solution providing end-to-end integration. Versa Cloud ERP delivers a centralized platform linking critical systems. Real-time data sharing across accounting, inventory, manufacturing, purchasing and warehouse management prevents delays and mismatches.

User-friendly access through any web browser or mobile device allows employees to handle receiving, put-away, production, sales orders and shipping seamlessly. Configurable dashboards offer analytics for optimizing workflows. Seamless 3PL and commerce channel integration completes the ecosystem.

By tying together crucial functions, Versa Cloud ERP enables warehouses to reach the next level of speed, accuracy and liquidity. The solution forms the command center for orchestrating and expanding optimization efforts beyond the four walls. Streamlined data exchange brings broader benefits across the supply chain — to proactively exceed rising customer demands.

Effectively manage your financials, accounting, inventory, production, warehouse management, order management, and other operations of your Shopify Store workflows with our award-winning ERP.

Let Versa Cloud Erp’s do the heavy lifting for you.

Empower your business with the knowledge to navigate the realm of an Integrated ERP solution. Gain insights, streamline processes, and propel your accounting management to new heights with this comprehensive guide.

With Versa Cloud ERP’s Implementation guide learn how a business can ensure a successful ERP Solution Implementation. Navigate the complexities of implementation with confidence!

A Small Business in the modern day with Omnichannel Retail is complex and requires resources to deliver on its goals and achieve its full potential. To create a small business success story business owners need an ERP Solution that grows with them.

Do Business on the Move!

Make your businesses hassle-free and cut the heavyweights sign up for the Versa Cloud ERP today!!

Join our Versa Community and be Future-ready with us.