In today’s fast-paced business landscape, supply chain management stands as a critical pillar for organizational success and an ERP solution plays a crucial role.

As companies strive for greater efficiency, agility, and customer satisfaction, the ability to forecast demand, manage inventory, and streamline logistics has become paramount. Real-time reporting has emerged as a powerful tool in this endeavor, offering insights and visibility into every aspect of the supply chain.

Supply Chain Forecasting Module in an ERP Solution: The Key to Success

Accurate demand forecasts are essential for efficient supply chain management. However, with many quantitative and qualitative techniques to choose from, where do you start?

We will try to break down the key concepts and strategies your business needs to choose the right forecasting models and boost predictive accuracy.

Why Supply Chain Forecasting Matters

Today’s complex omnichannel environment has made precise demand predictions more critical than ever. Research shows most manufacturers still only forecast 65-70% accurately.

Without good forecasts, you risk stockouts, excess inventory, and suboptimal customer experiences. Manufacturing depends on forecasts for production planning. Retailers need accurate projections for staffing, promotions etc.

By improving forecast precision, you build supply chain resilience, avoid disruptions and deliver next-level customer service. The path to supply chain excellence starts with quality demand insights.

Supply Chain Forecasting Module in an ERP Solution: The Approach

From time series analysis to causal modeling and machine learning, many mathematical and statistical techniques exist for demand sensing. You need to select approaches aligned to your lead times, seasonality, channel complexity etc.

Time series models like moving averages or ARIMA rely solely on historical data to uncover trends. Causal techniques additionally model variables that influence demand like promotions. Machine learning algorithms automatically uncover complex patterns to sharpen projections.

Steps to Improve Forecasting

With the right strategies, 85-90% accuracy is possible. Best practices include:

- Cleanse data at the source to avoid “garbage in, garbage out”

- Increase forecast frequency for responsiveness

- Incorporate leading indicators of demand

- Blend statistical and expert human judgement

- Continually review errors to refine models

The key is choosing approaches tailored to your products and markets. By following these steps, you’ll be on the path to supply chain success.

Breaking Down Common Supply Chain Forecasting Approaches

From simple time-series extrapolation to sophisticated machine learning algorithms, numerous quantitative and qualitative techniques exist for predicting demand signals. Choosing the right approach depends on factors like product characteristics, lead times, seasonality, and channel complexity.

Time-Series Forecasting

Time-series analysis leverages historical demand data to identify seasonal, cyclical or gradual trends and patterns. By extrapolating insights from the past into the future, time series models include:

- Moving Averages: Forecasts are based on the average of a fixed number of the most recent periods. A simple way to smooth demand, but be responsive to recent changes.

- Exponential Smoothing: Places greater weight and significance on more recent demand data to predict trends. Allows for seasonal adjustment factors.

- ARIMA Models: Combine past values and past errors to predict future values using three parameters (autoregressive, differencing, moving average). Can account for non-stationarity in time series data.

Causal Forecasting

While time series analysis relies solely on historical demand patterns, causal techniques incorporate additional variables that potentially influence demand. For example: promotions, pricing changes, product launches, economic factors, weather events or market influencer activity.

By quantifying and modeling causal relationships, you can better anticipate the impacts of marketing campaigns, new product introductions, or changes in leading economic indicators. Regression analysis is commonly used for causal modeling.

Machine Learning Forecasting

Machine learning leverages algorithms that study data to uncover patterns, learn from experience, and improve decision-making over time automatically without explicit programming. For forecasting, common ML approaches include:

- Neural Networks: Inspired by human brains, these interconnected nodes identify complex relationships between inputs and outputs based on training data to refine predictions.

- Random Forests: An ensemble learning technique that averages the results of many decision trees based on random input samples to deliver high-accuracy forecasts while avoiding overfitting.

- Support Vector Machines: Uses past demand data to define decision boundaries and margins that optimize new predictions. Effective for nonlinear trends.

Supply Chain Forecasting Module in an ERP Solution: The Path Forward

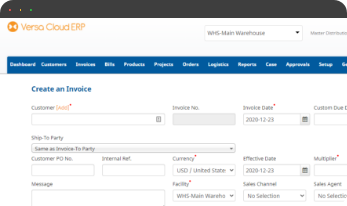

As discussed, achieving supply chain forecasting excellence depends on the blend of strategies, processes, technologies, and cross-functional alignment. Purpose-built solutions like Versa Cloud ERP provide an invaluable digital backbone to drive end-to-end visibility, coordination, and decision-making.

Versa Cloud ERP delivers best-in-class inventory optimization and demand forecasting capabilities out-of-the-box with real-time analytics to continually improve predictive insights over time. This allows you to achieve synchronized operations, minimize waste, and delight customers across procurement, manufacturing, sales, and delivery processes.

With real-time data feeds and scenario analysis, supply chain leaders gain the agility to swiftly correct the course based on risks and opportunities as they emerge. By leveraging Versa Cloud ERP’s tools and analysis, you can streamline planning cycles while amplifying forecast accuracy. Contact us to learn more about intelligently transforming your supply chain operations for a competitive edge.

With Versa Cloud ERP’s Implementation guide learn how a Manufacturing business can ensure a successful ERP Solution Implementation. Navigate the complexities of implementation with confidence!

A Small Business in the modern day with Omnichannel Retail is complex and requires resources to deliver on its goals and achieve its full potential. To create a small business success story business owners need an ERP Solution that grows with them.

Effectively manage your financials, inventory, production, and warehouse management workflows with our award-winning ERP.

Let Versa Cloud Erp’s do the heavy lifting for you.

Do Business on the Move!

Make your businesses hassle-free and cut the heavyweights sign up for the Versa Cloud ERP today!!

Join our Versa Community and be Future-ready with us.