In today’s dynamic business landscape, an effective inventory warehouse management ERP Solution is crucial for ensuring smooth operations and maintaining a competitive edge.

Managing inventory and warehouse operations efficiently is vital for meeting consumer demand, minimizing costs, and staying competitive. This comprehensive guide explores key strategies across layout optimization, process enhancement, advanced forecasting, inventory control tactics, and technological integration to help warehouses operate at peak performance.

Optimizing Warehouse Layouts and Storage Density

Carefully designing warehouse layouts based on intuitive zoning, efficient material flows, and storage density optimization is fundamental. Key considerations include:

- Storage and Racking Design – Leverage vertical space via multi-level racking structures and mezzanines. Optimize racking aisle dimensions and slot angles to maximize storage density. Implement modular shelving and bins to accommodate variously sized stock.

- Zoning and Slotting Plans – Designate focused activity zones like high-velocity “Fast Pick” areas near shipping bays for fastest-moving items. Position slow-turn inventory in longer-term storage zones with denser racking to improve space utilization.

- Automated Optimization – WMS inventory slotting algorithms can create optimized zoning maps based on product dimensions, affinity, velocities, and other attributes. This levels picker workloads and reduces travel distance.

- Flexible Layouts – Built-in versatility to rearrange zone configurations or add modular racking allows adapting to evolving inventory needs. Identify seasonal peaks and valleys in advance.

Process Enhancements for Efficiency

Streamlining processes around inventory movement, storage, and order fulfillment improves productivity while reducing errors and waste.

- Implementing FIFO – First-in-first-out order picking ensures utilizing the oldest received inventory first before new stock. This prevents wastage from expiry and storage congestion.

- Facilitating Cross-Docking – Directly dispatching incoming inventory to fill orders without storage avoids put-away delays. This requires coordination with suppliers and transporters.

- Error-Proof Workflows – Leverage barcode scanning, RFID tagging, pick-to-light systems, and wearables to eliminate manual entry errors. This improves inventory record precision.

- Labor Planning – Carefully match staffing to expected order volumes based on sales forecasts and seasonal spikes. Cross-train employees for agility across functions.

Enhanced Forecasting for Leaner Stocking

Accurately forecasting demand well ahead of lead times ensures lean stocking while avoiding stockouts.

- Statistical Models – Time-series algorithms analyzing past demand patterns improve predictability for stable products. AI-based neural networks help forecast irregular sales.

- Buffer Stock Calculation – Simulation models determine minimum buffer stock levels to account for variability in supply, demand, and lead times. Define stockout risk tolerance.

- Multivariate Analysis – External causal factors like promotions, climate, or channel shifts significantly influence future consumption. Quantify such cross-impacts.

- Continuous Optimization – Incrementally refine algorithms as new sales data emerges to boost responsiveness. Rapidly adjust stock norms to account for outliers.

Inventory Control Tactics

Employ inventory management techniques centered on JIT stocking, frequent cycle counting, and multi-echelon visibility for accuracy.

- Just-in-Time Inventory – Hold no excess buffer or safety stock. Closely coordinate with suppliers to replenish only what is required to fulfill orders. This minimizes holding costs.

- ABC Classification – Categorize products as fast-moving (A), slow-moving (B), or non-moving (C) items. Assign differential cycle counting and monitoring frequencies based on criticality and risk.

- Regular Cycle Counts – Perform daily or weekly cycle counts on samples of inventory to maintain high precision. Investigate count discrepancies for root causes.

Warehouse System Integration

Modern warehousing calls for a connected technology ecosystem providing system-wide visibility, business insights, and workflow automation.

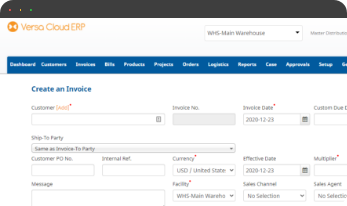

- Warehouse Management System – A robust WMS enables inventory tracking, order orchestration, and analytics on a common platform via the cloud. Integrate predictive capabilities.

- Material Handling Automation – Automated storage and retrieval systems substantially multiply throughput capacity and inventory control while minimizing human handling.

- Mobile and Wearable Devices – Handheld RFID readers, barcode scanners, and voice-directed headsets optimize human task efficiency and output quality.

- IoT Sensor Integration – Install environmental sensors on inventory to track locations, conditions (temperature, moisture, etc.), and state changes (vibrations, motion, etc.) in real time.

- Unified Data Analytics – Consolidate operational data across systems into a common data lake. Perform statistical analysis to identify improvements. Develop interactive dashboards that deliver contextual insights.

By holistically transforming inventory planning strategies, warehouse layouts, storage density, inventory tracking processes, and integrated technologies, enterprises can realize substantial long-term cost savings, higher order fulfillment rates, and sustainable competitive advantage. The journey calls for incremental improvements guided

Versa’s All-In-One Business Management Solution

As this comprehensive guide illustrates, transforming your warehouse management and inventory control practices can drive tremendous efficiency gains, cost savings, and competitive differentiation. To further explore how a modern ERP like Versa Cloud ERP can empower your business, schedule a free customized demo today.

See how Versa Cloud ERP’s robust warehouse and inventory management modules can centralize tracking, optimize planning, and enable seamless integrations tailored to your unique requirements. With real-time data visibility, scalable cloud infrastructure, mobility features, and machine learning-driven insights, Versa digitally future-proofs your supply chain operations. Sign up now to experience these game-changing capabilities via an interactive, personalized demo and propel your business to new heights.

Empower your business with the knowledge to navigate the realm of an Integrated ERP solution, specifically tailored to inventory and warehouse management and POS needs. Gain insights, streamline processes, and propel your financial management to new heights with this comprehensive guide

With Versa Cloud ERP’s Implementation guide learn how a business can ensure a successful ERP Solution Implementation. Navigate the complexities of implementation with confidence!

A Small Business in the modern day with Omnichannel Retail is complex and requires resources to deliver on its goals and achieve its full potential. To create a small business success story business owners need an ERP Solution that grows with them.

Effectively manage your financials, accounting, inventory, production, and warehouse management workflows with our award-winning ERP.

Let Versa Cloud Erp’s do the heavy lifting for you.

Do Business on the Move!

Make your businesses hassle-free and cut the heavyweights sign up for the Versa Cloud ERP today!!

Join our Versa Community and be Future-ready with us.